Be it a smartwatch you wear in your day-to-day life or an MRI machine in a large healthcare facility. Everything has a PCB at its core. It’s the brain controlling the functioning of the device.

Medical PCB manufacturing is becoming more complex as the medical devices are becoming compact, fast & stylish. Smart wearable medical technology, fast-paced monitoring & diagnostic tools require efficient electronic design. PCB and electronics are significant as more precision and automation are necessary to develop futuristic medical technologies in compliance with regulatory to fulfill the industry demands.

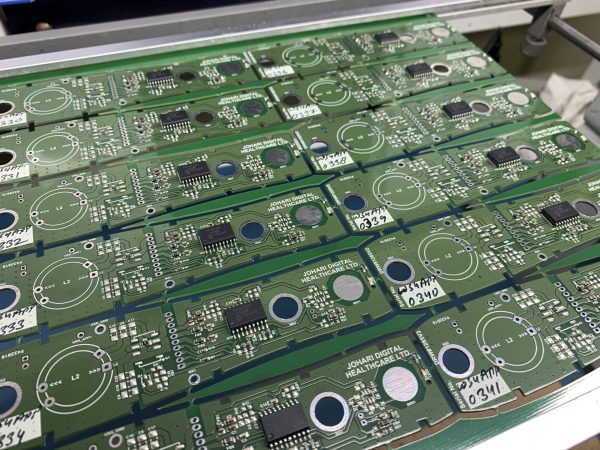

Johari digital is an industry-leading electronic medical device manufacturer offering medical PCB assembly, design services and contact manufacturing over 40 years. We strictly comply with industry standards of ISO 13485 & US FDA during the PCB assembly process. As a result, we produce a PCB that ensures your medical device works efficiently and is safe to use.

What types of medical devices PCB We design?

#1. Wearable Technologies

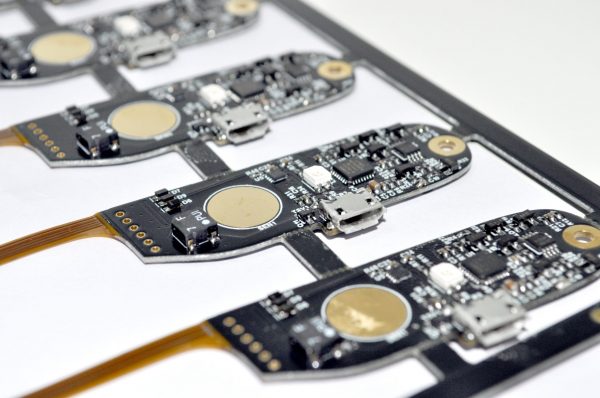

We design flexible PCBs for smart wearable technologies. Johari Brand iNishCalm is one the most premium US FDA cleared CES based device to help in Insomnia and Anxiety. The Flexible PCB used in this device makes the device user-friendly, functionally advanced and aesthetically pleasing. The device has been ergonomically designed to withstand user’s expectations.

Characteristics of Flexible PCB

- The flexible PCB is made out of lighter material so weight of the device is reduced.

- The bending property of Flex PCB makes it easier to reduce size and optimize cost of manufacturing.

- Flex PCB make it easier to mould the device into various shapes. Thus, making its aesthetic appealing.

- Although, designing a flex PCB is complex but the sturdiness of the design cannot undermine. 99.9% of flex PCB ensure an ergonomic user-friendly device.

#2. Life Science/ Diagnostic Device technologies

Gone are the days when people waited for a week to get their sample results. The instant testing kits for Pregnancy, Diabetes, Blood tests are the new market demands. These devices require compact sized PCB, Flexible PCB or multilayer PCB to enable portability, compactness, light weight and exclusive high-speed functionality. The lab procedures require advanced IoT, ML and AI based devices like Homogenizers, samplers and diagnostic equipment.

The wireless protocols for these devices make the task of designing their PCBs complex. But, with our 40 years of experience in the field, we design durable PCBs for smart wireless Diagnostic tools. The PCBs ensure signal integrity and keep the device performance maximal with minimum heating & power consumption.

At Johari, we have experts encompassing excellence in designing PCB for futuristic telehealth technologies. As Telehealth is expanding its reach, we are also gearing up to produce equipment promoting remote patient access. The Blood sample testing device by Johari is a next-generation cloud-based diagnostic solution for accessible and affordable screening.

#3. Electrotherapy Equipment

Electrotherapy equipment deal with human life and it’s extremely important to keep quality as priority while dealing with human life. These devices are designed in various formats from desktop & handheld models to portable models. All these require a different type of PCB. Some might require single layered PCB while others may need a multilayer PCB. Each PCB differs from the other in terms of functionality and efficiency it delivers in the equipment being produced. A multilayer PCB is highly advanced form of PCB where component space and track space are reduced. At Johari, we design single layered to multi layered PCBs. In our 40 years of experience, we have handled numerous complex projects efficiently. Therefore, our experts can assist you with relevant challenges in PCB design too.

Single layered PCB

Single layered PCBs are easy to design as they are cost efficient and do not require complex componentry. One of our brand product Flex-E-Tone EME 123 uses this type of PCB to deliver excellent functionality for muscle strengthening & toning.

Characteristics Single Layered Rigid PCB

- Provide resistance against breaking & bending of circuit.

- These are aptly suitable for analogue and digital circuits.

- Perfect for usage in sensor-based devices.

- Cost Efficient to Design

- Time required for correcting the faults is less

- The drilling, soldering, de-soldering of components is easy for Rigid PCB.

Multi-layered Rigid PCB

A multi-layered PCB comprises of at least 3 layers of conductive material. The layered PCB reduces size of the device and optimizes power consumption. At, Johari we can design Multilayer Rigid PCB for hand held face-lifting & toning devices at optimum cost. Our advanced capabilities in PCB Design, Assembly & Testing make us competent to customize technology for user’s delight.

Our wide range of Electrotherapy equipment including Analgesic Pulsar Next-AP4390, JUS-1 HF, Wellstim, Winstim and Hand-Held electrotherapy devices (Stimtec-2) use Multi layered Rigid PCB designed in our facility. Our PCBA processes ensure high quality automated components placing, multi-level testing and inspection. The lead-free soldering of components ensures RoHS compliance of every PCB in assembly.

Characteristics of Multi-Layered PCB

- A multilayer PCB count between 4- 32 layered.

- Minimal impedance leads to high quality

- Ultra-Fine- pitch

- Small hole drilling, laser drilling

- High quality Construction

- Improved Durability

- Single Connection point for small gadgets

- Greater Capacity and speed due to high density assemblies.

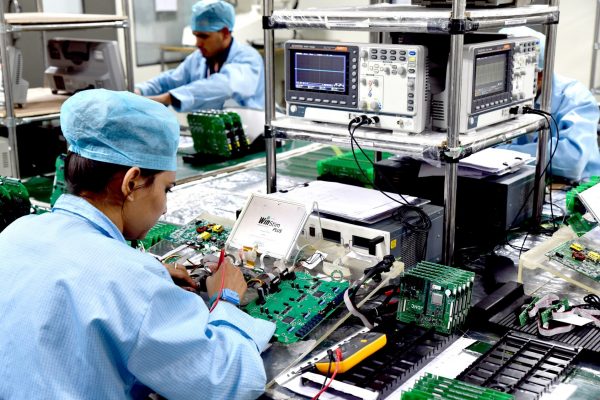

Our PCB Manufacturing Capabilities

Johari Digital holds firm ground in terms of capability, quality, and cost in PCB design and assembly. We have seen the changing trends of the medical device industry over 40 years and this makes us the most preferred and worthy manufacturing partner. Our adherence to FDA guidelines and strict QMS ensures continuous evolution in our processes. The check-balance and improvement every day makes us a reliable medical device manufacturer. The expansion of our capabilities in PCBA makes us a global dominant in medical PCB manufacturing.

Our PCB manufacturing capabilities include:

- Surface mount technology

- Through Hole Manufacturing

- 8 Zone Reflow oven

- Lead free soldering

- Automated optical inspection

- Automated temperature control

- Inspection & multiple Testing

We are excellent at:

- Inspection & Testing – As a leading contract manufacturer, we take inspection and testing of PCBs very seriously. We ensure quality delivery with the stipulated timeline.

- Supply Chain Management – We have strict QMS, 400 verified vendors, vetting process and documentation in place to ensure quality components for PCB manufacturing.

- Design Validation – We evaluate the design for manufacturability to optimize the PCB manufacturing process. Our experts can also recommend redesign and arrange suitable components and parts to reduce cost, improve quality and meet the regulatory requirements.

If you require medical pcb assembly and design services, please free to