Research and Development

Johari Digital Healthcare Ltd is one of the most renowned Original Equipment Manufacturer having MDSAP & cGMP certified manufacturing in India and R&D in Europe.

DEVELOPMENT TEAM

Johari’s Research and Development team includes highly qualified and experienced professionals who are focused on applying leading-edge innovation and technology to your medical product concepts. The R&D team can contribute to the success of your project through strong engineering expertise in circuit design, PCB layout, software development, test engineering, and product development. We can modify/customize your existing products for better aesthetics and improved performance at an optimized cost of production.

- Ability to quickly turn concepts into detailed product design.

- OEM Service: Technology research and product concepts.

Medical Device OEM Services – Integrating Excellence

Being the Original Equipment Manufacturer, our R&D is passionate about medical device design and development. Our manufacturing spans across IVD devices, biomedical devices, physiotherapy devices, and diagnostic devices.

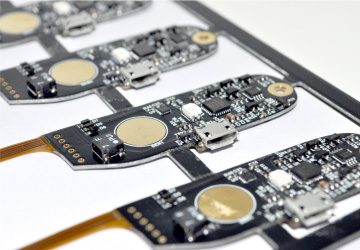

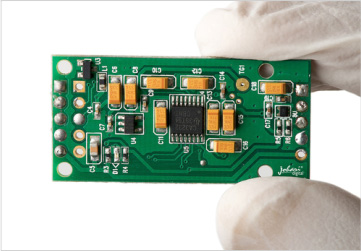

Electronics Design & Manufacturing

We provide quick-turn prototype, low-volume and production PCB assembly with surface-mount (SMT), through-hole (THT) and mix components. We offer turn-key (just send us the Gerber and BOM files), consignment (you supply all parts) and various components purchase options to help you reduce cost and time to market. We can handle small quantity as well as volume productions.

- PCB layout & design

- Capacity of 1000+ PCB production per day

- Surface Mount Technology (SMT)

- Class 100,000 clean room electronics manufacturing

- 5 Parallel Product Assembly Lines

- Flexible, Rigid & Multilayer PCBs

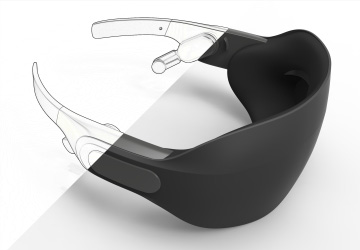

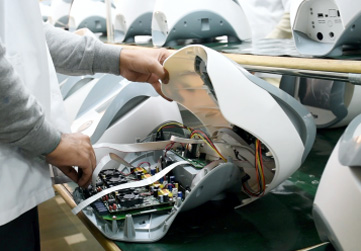

Industrial Design

Being known as OEM service provider, Johari Digital is passionate about crafting unique industrial design for every product. You’ll find cutting edge creativity brought to you by designers who understand what it takes to work alongside engineers to bring innovative products to market efficiently. From human factors to user experience, our expert designers work with clients to bring, easy-to-use & thoughtfully designed technology to life.

- Ideas and conceptualizing

- CAD design & drafting

- Prototyping & validation

- Molds & tools designs

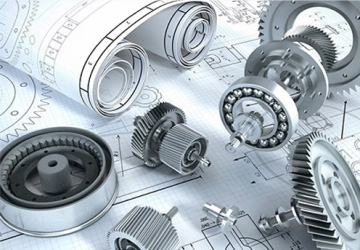

Mechanical Design

Johari Digital provides In-House Mechanical Engineering Services. Our design Engineers use advanced CAD and Solid Works software to create designs that are not only mechanically stable but also aesthetically appealing.

- Cable and wire harness, clipping and striping

- Box Build: Injection molding, casting and sheet metal

- Enclosures and housing

- 3D Printing and Rapid Prototyping

- Plastic Injection Molding

- EMI/RFI Shielding

Graphical User Interface

We keep the accessibility & ease of use on priority. Our intuitive and user-friendly GUI ensures smooth & interactive experience.

Industrial Aesthetics

We create flawless, aesthetically appealing, and user-oriented medical/healthcare devices. Each prototype goes through ergonomic product development or “ergonomic audits” to evaluate performance and user satisfaction on multiple grounds. Whether it is graphical, industrial, or structural packaging design, we ensure a seamless transition from concept sketches to the final product.Read more..

Packaging

We make packaging easy for you. With our finest services and efficient supply chain around the world, we assure to deliver the packages conveniently from their manufacturing home in India. We provide customized solutions to design your packaging to suit your brand outlook. Read more..

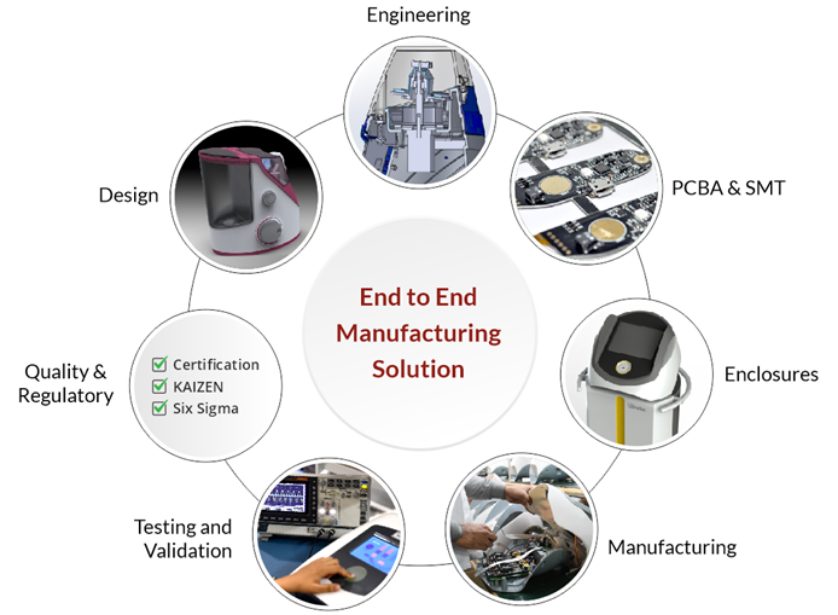

Turn Key Solution

Being the leading OEM service provider, we offer complete end – to – end medical equipment manufacturing services, allowing our customers to gain the benefit of supply chain consolidation, manufacturing efficiency and lower costs. We are constantly integrating innovative technologies and processes with futuristic ideas in collaboration with our partners. With access to flexible printed circuitry, 3D Printing, Surface Mount Placement(SMT), Wave Soldering, Optical Inspection, Microelectronics, Advanced Sheet Metal Forming, and Class 100,000 clean rooms, our facility is well equipped to turn your ideas into the products of future.

Design for Excellence

OEM Service: The Key to Simplicity, Quality and Cost Savings

Turn Prototype into

Manufacturable Solution

Our OEM service involves simplifying manufacturing activities, minimizing the diversity of components, and standardizing the handling and assembly operations. In design phase we pay special attention to Critical Components Planning, Manufacturing Frequency Estimates, and Tooling or any other one-time activity concerning quality.

Optimize Existing

Manufacturing Process

Being able to offer Key-Turn solution for your products, we are uniquely positioned to optimize your manufacturing processes. Our DFM Group, Planning Group and Automation Group can help create and execute Optimization Plan that results not just in cost savings, but also in a simpler, more effective manufacturing lifecycle and stronger business performance.

Optimize Cost through SAP

Material and Resource Planning

Once mass manufacturing is set in motion, we move on to optimizing costs through Material and Resource Planning. With 40+ years of experience, we have partnered with the biggest/trusted component suppliers to create cost-effective component purchase processes, meeting the stringent quality demands needed for medical product manufacturing.

Global Supply Chain Solution

With our integrated well-established network of industries, suppliers, and distribution partners, you get enhanced visibility with minimum overhead, and a more stable, balanced supply chain, responsive to fluctuating market demands. We have a number of distribution and service centers to help you deliver your product and service with quality and optimized cost within the stipulated timeline.

Partner Integration

Working with Johari Digital, you will realize we work for mutual growth with highest focus on customer centricity.

-

IP Protection

100% Commitment to IP Protection. Having a long history of handling our own and our partner’s IP we know the value of sensitive data. Along those lines, we pro-actively establish, monitor, and enforce security protocols to limit access to sensitive data.

-

Integrated Planning

When you partner with Johari, you will become a crucial part of our MDSAP-based processes. Plan, schedule and monitor manufacturing resources, to ensuring timely delivery of your products

-

Lifecycle Management

It does not end with the product being out of our door and we know that. Whether it is repair, spare parts or refurbishing, we are ready and equipped to support you every step of your way.

-

Vendor Transparency

We transparently share logistics, quality, and cost information from vendors with our clients. This information is leveraged to optimize your supply chain for quality and cost.

Get in Touch